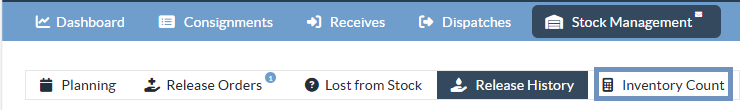

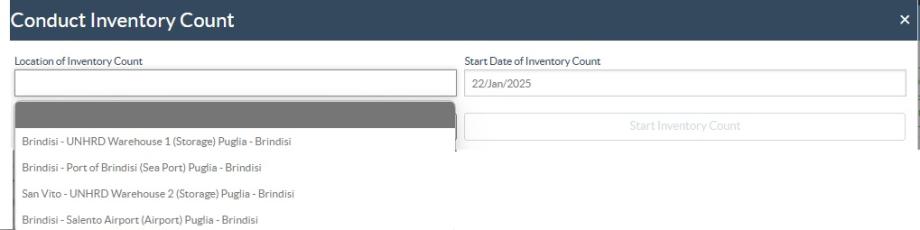

This function enables RITA users to directly conduct and manage physical inventories through RITA. Simply click on "Inventory Count" from the "Stock Management Tab."

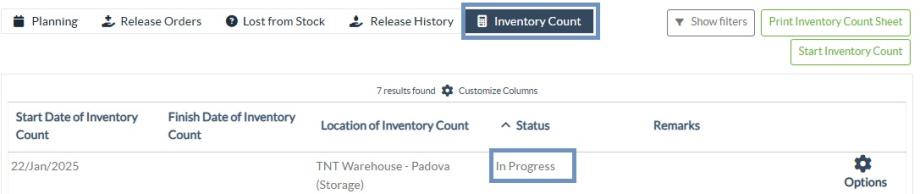

In the “Inventory Count” tab, operators will by default see a list of all past inventories that were conducted and are able to print the results of those inventories. The “Show filters” option assists RITA operators in easily searching for past inventories and generating historical records using consignment number, date of inventory count, and other relevant properties.

Print Inventory Count Sheet

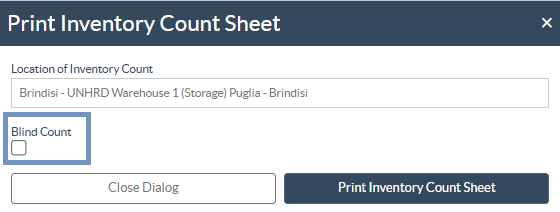

This option enables RITA operators to print the inventory count sheet containing the list of items located at any warehouse location requiring a physical inventory. Printing the inventory count sheet enable warehouse or project managers to conduct a direct “offline” inventory using printed sheets.

The printed inventory form has a feature called “Blind Count”, clicking on which, the managers can only print the list of consignment line items stored in the warehouse without the item count.

Start Inventory Count

This option enables the RITA operator to follow the steps for conducting inventory count using RITA physical inventory. The outlined steps for inventory count are as follows:

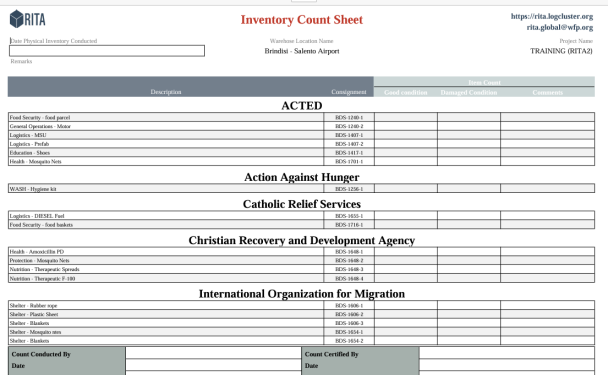

Step 1: Click on the option “Start Inventory Count” on the top right section of RITA

Step 2: Select the warehouse for the inventory count and pick the starting date for the physical count.

When you choose a warehouse for the inventory, all transactions in that warehouse will be put on hold. This allows the warehouse teams to do a complete count. You cannot conduct the inventory count if there are planned transfers or committed stock in the warehouse.

RITA operators cannot perform any transactions in RITA on the day of the inventory count, even after the count is finished. They must wait until the next day to make updates in RITA. Additionally, RITA operators cannot reconcile transactions that happened before the inventory count. Any dispatches or receipts of cargo at the storage location prior to the inventory date are not allowed.

Step 3: RITA will display a list of all items in the warehouse along with their existing inventory in the system. Operators can begin the physical inventory by clicking on "Start Inventory Count." The status of the inventory count will change to "in progress."

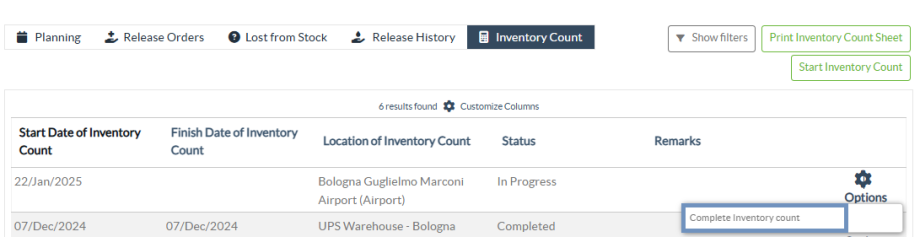

Step 4: After conducting physical count, operator must select "Complete Inventory Count"

Note: Completing an inventory count involves entering the results of the inventory. In small warehouses, or those with reliable internet connectivity, inventories can often be conducted directly through the web interface. However, in most cases, the inventory count will be based on the results from "offline" paper inventory count sheets. Depending on the size of the storage location and the number of unique items stored, updating the physical inventory numbers may take a considerable amount of time. Ideally, only managers with authorized access should enter the final numbers.

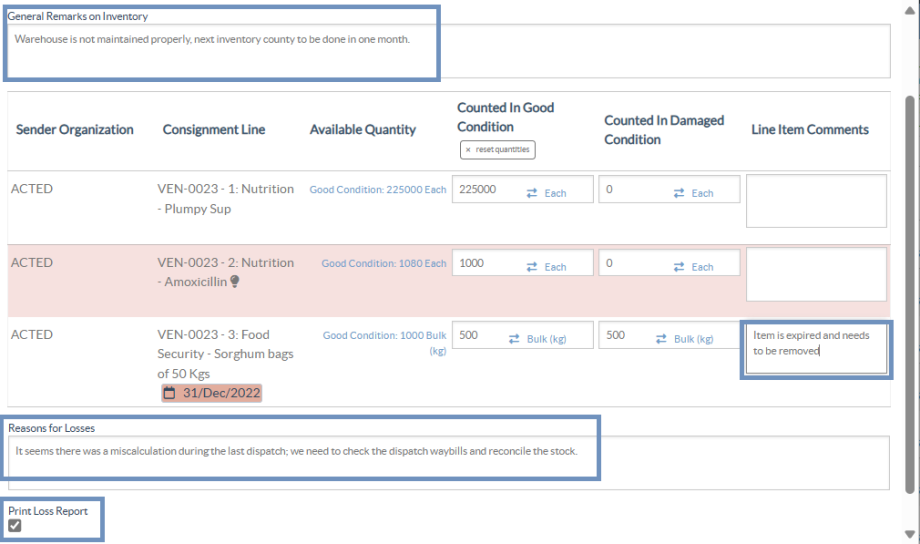

Step 5: A pop-up box will appear, allowing RITA operators to input the physical count of the items. Users can enter the quantity of items in good and damaged condition, along with any comments. The system, RITA, will automatically calculate the remaining items as losses. Operators can also include overall remarks for the inventory. Additionally, when a loss is reported, a comment box will appear to allow the user to provide reasons for the loss. Further clicking on the loss report will generate an automatic loss report from the system.

Finally, click on "Complete Inventory" to change the physical inventory status to "Completed."

Step 6: The system will maintain a record of all previous inventories, and users will be able to generate reports for future requirements.

| When you chose a warehouse for physical inventory, all transactions in that warehouse will be put on hold, allowing the warehouse teams to perform full counts. The inventory count cannot be conducted if there are planned transfers or committed stock in the warehouse. |

Upload attachment

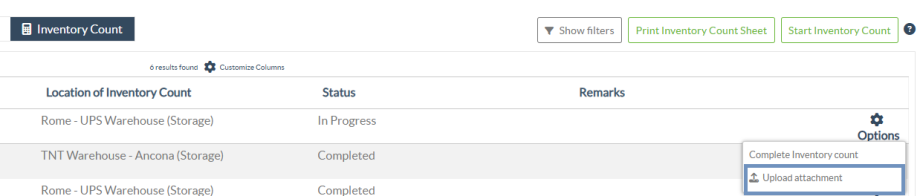

RITA allows users to upload completed physical inventory files directly to the inventory record. The uploaded document will be linked to the corresponding inventory count for reference.

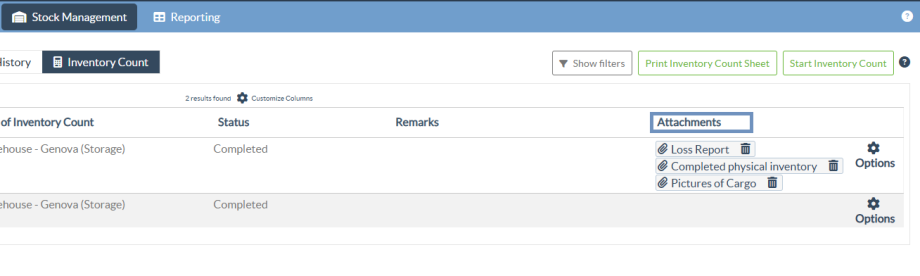

Step 1: From the Inventory Count page, once the inventory status is marked as Completed, click on the "Options" icon and select Upload attachment.

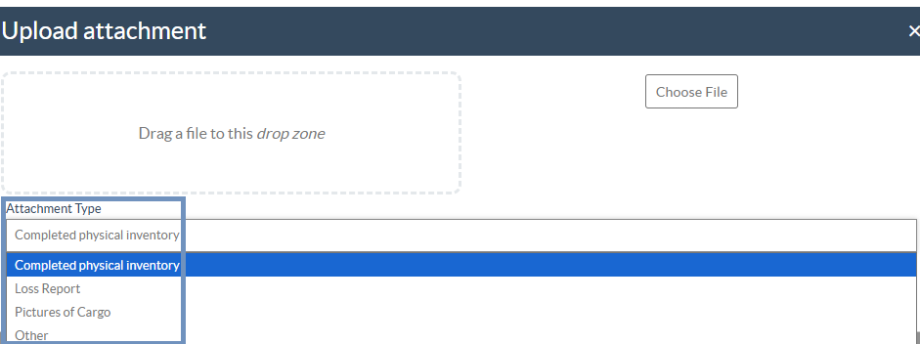

Step 2: In the upload window, drag the desired file into the drop zone or click "Choose File" to select it manually. From the Attachment Type dropdown, select the appropriate category:

Completed physical inventory - to attach finalized physical inventory sheets.

Loss Report - to upload documentation related to reported losses.

Pictures of Cargo - to include photos taken during the inventory or inspection.

Other - for any additional supporting documents.

Step 3: All uploaded attachments appear under the new Attachment column in the Inventory Count list, where users can view or delete files as needed.

|

|